What is Bentonite?

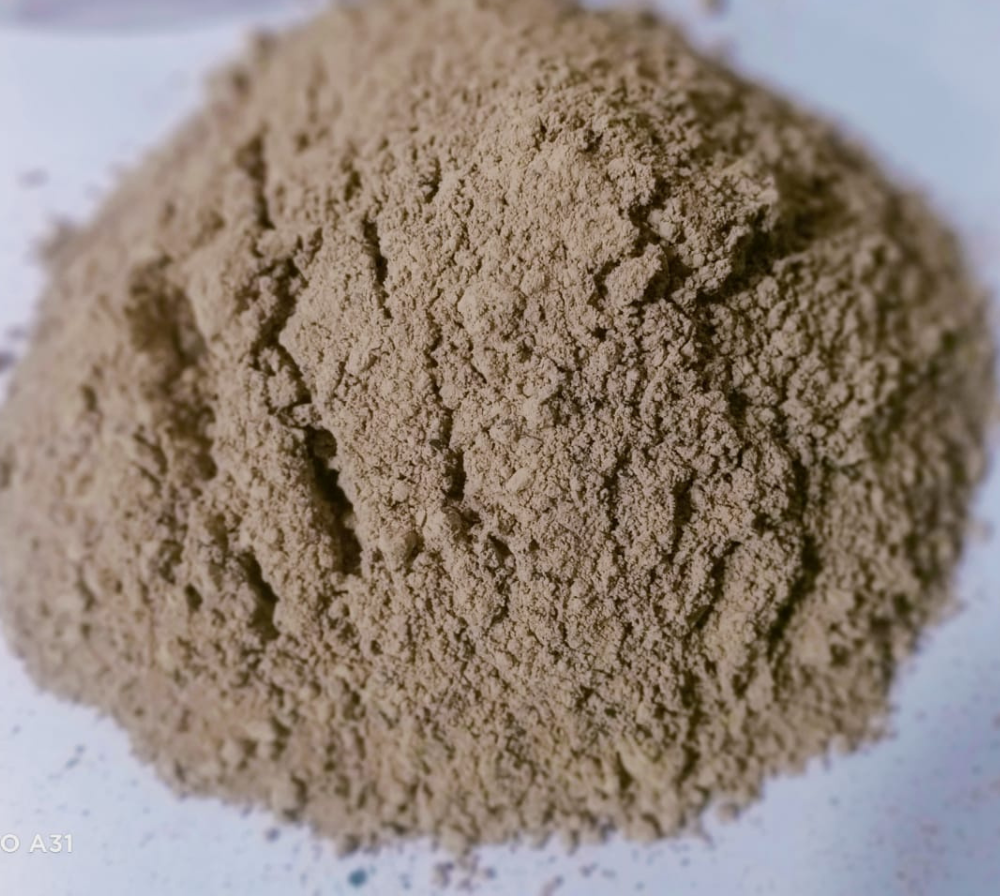

Bentonite is essentially a plastic clay which contains clay mineral “Montmorillonite”.

The name BENTONITE comes from the area in the USA where its presence was first discovered – the Cretaceous Benton Shale near Rock River, Wyoming and was named as “Bentonite” by Fielding Bradford Meek and F. V. Hayden of the U. S. Geological Survey in mid 19th century.

Bentonite’s commercial importance is due to its inherent bleaching properties similar to that of fuller’s earth. Hence, it is also used as bleaching clay, after some modifications. Due to its plastic property, it is also used in Foundry and palletisation industry.

There are two types of bentonites, namely, swelling-type or Sodium bentonite and non- swelling-type or Calcium bentonite.

The commercial importance of bentonite depends more on its physico-chemical properties rather than its chemical composition. Excellent plasticity & lubricity, high dry-bonding strength, high shear & compressive strength, low permeability and low compressibility make bentonite commercially viable.

Bentonite is valued in applications, such as, foundry sand binding. drilling mud, iron ore palletisation and as a waterproofing & sealing agent in civil engineering works.

Processing is a prerequisite for bentonite marketing.

Bhavnagar and Kachchh districts of Gujarat and Barmer district of Rajasthan are the major producing areas of bentonite in India.

BENTONITE USES

IRON ORE PALLET INDUSTRY:

Iron Ore is found in rock form and has to be broken into small sizes for making commercial use. However, crushing of iron ore produces a large amount of iron ore fines, which cannot be fed into furnaces to make steel. The fines are then made into pallets. Bentonite is well suited as a binder in the making of iron ore pellets from Iron Ore fines. Owing to high green strength resulting from its property to absorb and then release moisture, bentonite is used in iron ore palletisation.

FOUNDRY INDUSTRY:

Foundry industry uses moulds made of foundry sand. However, the foundry sand does not have any plasticity and Bentonite is added as a binder in the sand for making the moulds. Bentonite exhibits good green strength along with high hot and dry strength which helps in preventing moulds from breaking or cracking during the pouring or cooling process in the foundry industry.

OIL WELL DRILLING INDUSTRY:

Bentonite is used as a suspending agent in oil well drilling and as oil well drilling/ plugging mud.

CIVIL CONSTRUCTION INDUSTRY:

Due to its water holding capacity, Bentonite is used in civil construction industry in making of pillars of bridges and highways and underground constructions.

ELECTRICAL EARTHING:

Due to its high water adsorbent capacity, Bentonite is used as a Ground Enhancement Material (GEM) or Back Fill Compound (BFC) in electrical earthing. Bentonite is used alone or in combination with some other enhancement material for electrical earthing.

OTHER USES:

- Bentonite clay is also used in pyrotechnics to make end plugs and rocket engine nozzles.

- Bentonite has remarkable colloidal and waterproofing properties.

- Bentonite gels are used as a carrier for a number of cosmetic preparations, toothpastes, creams, etc.

- Bentonite is also used in Chemical, Rubber, Insecticide & Pesticide Industries.

- Bentonite in the form of fine powder free from dirt and other foreign matter and of least swelling property is used in Ceramic Industry.

- Bentonite which is the active mineral in clays with medicinal properties is also prescribed as a bulk laxative and it is also used as a base for many dermatological formulations.

- Bentonite is also used to prepare Sulphur Bentonite fertilizer (90:10) which is useful to impart better productivity.